- 2025-07-15

Seawater reverse osmosis

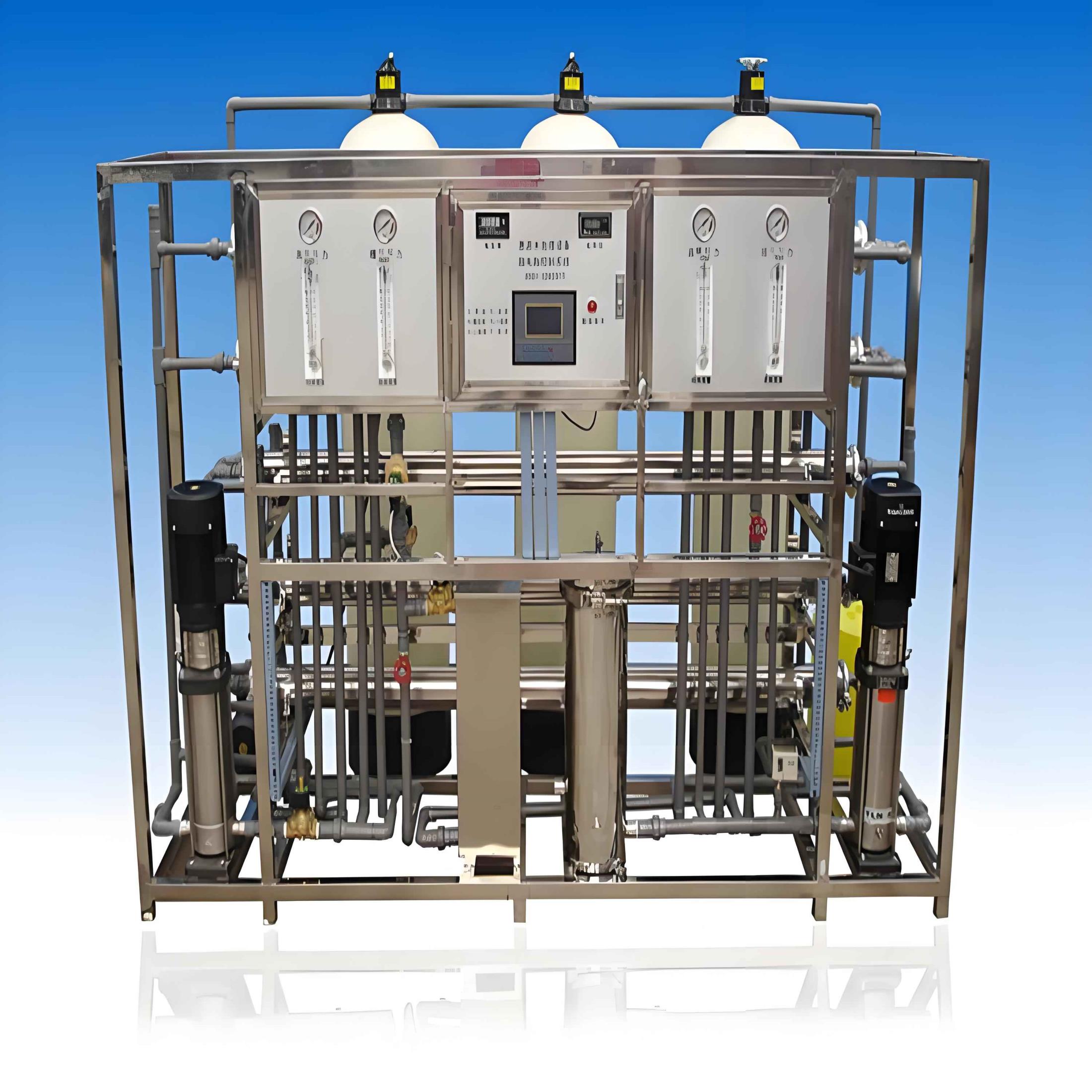

With over 23 years of experience, FupengWater is a leading global supplier of seawater treatment systems for a wide range of industries and applications. We offer a range of industrial and commercial seawater reverse osmosis systems designed to meet your desalination needs.

From desalination machines to industrial-scale seawater purification, we offer a full range of systems. Our seawater purifiers use reverse osmosis (RO) technology to remove large amounts of salt and other minerals from seawater. Our equipment uses high-pressure pumps to force seawater through a semi-porous membrane, which blocks the passage of salt and other organic matter.

Desalination uses osmotic membranes, which work to remove dissolved solids while separating the incoming water into pure water and concentrated salts. The salts and other organics are discharged into the brine stream and then discharged into the drain. The result is pure water with 99% less dissolved solids and salts. These seawater reverse osmosis systems are powerful enough to purify water with extremely high TDS values.

Seawater reverse osmosis systems are used in everything from yachts to municipal facilities. Choosing the right materials of construction to handle seawater, which is extremely corrosive, is critical. FupengWater uses materials such as Duplex 2205, Stainless Steel 2207 or Monel, and Stainless Steel 904 to ensure longer service life and less maintenance.

FupengWater has extensive experience in manufacturing water treatment systems for desalination worldwide. Our engineers provide consulting services to other desalination equipment manufacturers. Take advantage of our expertise. Contact FupengWater today for professional, friendly service and first-class support.

What is Seawater Reverse Osmosis?

Seawater reverse osmosis systems are designed to remove more than 99% of the salt in the feed water. These systems also include a flush chemical purification unit to remove sodium chloride, prevent scaling, and maintain system performance. Every seawater reverse osmosis system contains two basic elements: the reverse osmosis membrane and the high-pressure feed pump. These elements form the heart of any reverse osmosis system and require special consideration and application for successful operation.

Does reverse osmosis remove salt from seawater?

Yes, the semi-permeable membrane allows the feed water to pass through much more than the dissolved salts. Reverse osmosis systems work by applying pressure as fresh water flows through membranes, filtering out concentrated salts as well as minerals and contaminants from the incoming water. These unwanted impurities are either flushed away, recycled, or disposed of. Seawater reverse osmosis systems use multiple membranes to increase the amount of clean water produced each day.

What are the advantages of seawater treatment?

Seawater treatment has become an important alternative for producing pure fresh water in areas around the world where drinking water is scarce. The ocean provides an abundant source of water for humans as other sources of water, such as rivers, lakes, wells, and springs, are becoming increasingly depleted due to overexploitation. Although seawater is too salty to be used for drinking or most other purposes, the advent of seawater filters has made it possible to purify it.

A seawater purifier is a large-scale treatment facility that purifies seawater through a reverse osmosis process to produce fresh water. The seawater filtration system ensures that all harmful impurities that are present in large quantities in seawater are removed from the final water. As a result, seawater purifiers are seen as a major advantage in the water industry, as a reliable purification device that can provide large quantities of pure water to a variety of industries. Today, many important industries, such as agriculture and offshore applications, rely on seawater filters to supply clean water.

The Ultimate FAQ Guide for Seawater Reverse Osmosis Systems.

As freshwater resources around the world are becoming increasingly scarce, the popularity of seawater treatment is growing steadily. Through seawater desalination, more than 75 million people

have access to high-quality water. Currently, there are more than 22,000 seawater reverse osmosis plants in operation worldwide. Future forecasts show that the use of seawater reverse osmosis systems will increase exponentially as populations grow in coastal areas and desertification increases.

➣ What is a Seawater Reverse Osmosis System?

A seawater reverse osmosis system is a device that produces high-quality finished water by separating dissolved salts and other harmful components from salt water. The system relies primarily on high pressure generated by high-pressure pumps to inhibit the natural osmosis process.

There are many types of seawater reverse osmosis systems, each suitable for different applications. Due to the high salinity of seawater, seawater reverse osmosis units typically have TDS values between 35,000-45,000ppm. In addition, they tend to operate at higher pressures than brackish water reverse osmosis systems to achieve optimal results.

➣How does a seawater reverse osmosis system work?

Desalination is essentially a multi-stage process based on physical separation. The process involves pretreatment, membrane separation, and post-treatment. The following will detail the process of purifying seawater into fresh water using reverse osmosis technology.

Seawater contains larger particles such as algae, colloids, and debris, so sufficient pretreatment of the influent water is required. Usually, we use media and sediment filters to remove larger particles to prevent clogging of the reverse osmosis membrane. In addition, we use chemical agents or water softening technology to inhibit scaling or corrosion of important equipment.

The influent water from the pretreatment chamber is then injected into the reverse osmosis membrane under high pressure. Normally, water flows from low-concentration areas to high-concentration areas, but under pressure, the process is reversed.

The reverse osmosis membrane retains components with a molecular weight of 150-250 Daltons while allowing fresh water to pass through. As a result, fresh water without dissolved salts and other contaminants is collected as permeate, and harmful contaminants are collected as brine.

According to the complexity of the application to be implemented, the appropriate post-treatment procedures are adopted. For example, remineralization processes are often used to restore essential minerals. For some applications, post-treatment is not necessary because the permeate quality is usually excellent.

➣What are the advantages of using a seawater reverse osmosis system?

Desalination provides freshwater products for more than 75 million residents and thousands of industries. Seawater reverse osmosis equipment has been continuously improved over time, and system efficiency and output have also increased. The following is a list of the main advantages of contemporary seawater reverse osmosis systems.

➣What fields are seawater reverse osmosis systems used in?

The application range of seawater desalination systems is infinitely broad, and as freshwater resources are depleted, more and more industries are beginning to adopt seawater desalination technology. Due to its ability to produce excellent quality drinking water, seawater desalination systems are widely used in industry, commerce, and households. The following are some industries that use seawater reverse osmosis systems to meet their water production needs.

➣What is the cost of a seawater reverse osmosis system?

Modern seawater reverse osmosis systems are affordable and efficient water treatment solutions. By utilizing free resources, operating costs are significantly reduced. With the continuous integration of efficient technologies, equipment costs are also reduced. To better understand the financials of a seawater RO system, we will break down the operating costs for a system with a daily processing capacity of 10,000 tons.

• Electricity costs.

Seawater RO systems require electricity to start the high-pressure pumps and activate the control interface. For the above system, the cumulative electricity cost is 2.25 yuan per ton of water.

• Labor.

The operation of seawater RO systems generally requires skilled labor, especially in large-scale applications. The wages paid to workers are about 0.2 yuan per ton. However, labor costs vary depending on the prevailing labor prices in a particular area.

• Maintenance.

Timely and high-quality maintenance is key to the continued efficient operation of seawater RO systems. RO membranes need to be replaced regularly, with each replacement costing about 0.05 yuan, and maintenance costs about 0.04 yuan per ton.

• Depreciation costs.

Assets depreciate over time. However, the depreciation rate of seawater RO systems is relatively low. The depreciation cost of seawater RO equipment is about 0.12 yuan/ton. Therefore, the total cost of producing finished water using a seawater RO unit is about 4.54 yuan/ton.

➣What are the basic specifications of a seawater RO system?

Seawater RO systems are highly specialized equipment with unique features designed to achieve optimal performance in desalination. The main feature of a seawater RO system is its high TDS range, which can tolerate high salinity seawater. Here are the main specifications of a seawater RO unit.

➣What types of seawater RO systems do you offer?

Through continuous research and application of modern technology, FupengWater has developed a range of seawater RO systems. We offer unique systems that can efficiently meet the needs of a wide range of industries. Our main seawater RO systems include:

• Containerized seawater RO systems.

FupengWater offers seawater RO systems installed on 10-foot, 20-foot, and 40-foot ISO certified containers for a variety of applications. Containerized seawater RO systems are portable and easy to use, require no installation, and are simple to operate. They support different capacities and have different TDS tolerance levels (up to 45,000 ppm).

Maximum TDS level is 35,000-45,000ppm, upgradeable up to 50,000ppm.

Integrate with pre-treatment system. Daily processing capacity ranges from 1.4-2,500 cubic meters/day.

Energy recovery device. Working pressure up to 1200 psi.

• Skid-mounted seawater reverse osmosis system.

The seawater reverse osmosis skids we manufacture are made of stainless steel or titanium alloy, which can withstand high alkalinity seawater and will not corrode. All components are assembled on the skid with professional technology, which improves mobility and operation. These skids have excellent salt rejection rates and are suitable for small and large applications.

➣What factors should be considered when purchasing a seawater reverse osmosis system?

The complexity of seawater reverse osmosis systems and specific water production applications make the procurement process a bit cumbersome. However, knowing some background knowledge about seawater RO systems can simplify the purchasing process and ensure a perfect purchase. Our experts have summarized the following factors as key factors that users should consider before purchasing a seawater RO system.

➣ What is the optimal TDS level for seawater RO systems?

The high salinity of seawater requires seawater RO equipment to have a higher TDS tolerance than ordinary RO systems. The maximum TDS value of seawater RO systems used to desalinate extremely high salinity seawater is 50,000-55,000ppm. However, the typical TDS value of seawater is 35,000ppm, so the maximum TDS value of most seawater RO systems is 45,000ppm.

➣ What pretreatment procedures are deployed in seawater RO systems?

In general, all seawater RO systems are integrated with a pretreatment system. The pretreatment technology used depends on the seawater concentration. The main purpose of pretreatment is to ensure that all components that may harm the RO membrane and the entire seawater RO system are removed. The following are some commonly used

pretreatment systems to enhance the operation of seawater RO units.

➣What is the capacity of a seawater RO system?

Different seawater RO systems have different processing capacities and can generate different amounts of produced water in a specific time. Ideally, seawater RO units can be divided into three categories based on their processing capacity range: small, medium, and large systems.

Large-capacity seawater RO systems have a daily processing capacity range of 200,000 gallons per day to 900,000 gallons per day. Small-capacity seawater RO units have a daily processing capacity range of 380 gallons per day. FupengWater has broadened the range of seawater RO systems by customizing the daily processing capacity range.

➣How much energy does a seawater RO system consume?

High-pressure pumps and control panels are the main power-consuming devices in seawater RO systems. Due to the high salinity of seawater, higher pressures are required, so the energy consumption rate of seawater RO systems is higher than that of freshwater RO systems.

Nevertheless, deploying energy recovery devices in seawater RO units can help improve energy efficiency. It takes 3-6.6 kWh of electricity to desalinate one cubic meter of seawater using reverse osmosis technology. Higher flow rates also result in higher power consumption.

➣Can you customize a seawater RO system?

Over the years, FupengWater has provided more than 9,000 standard and customized water treatment systems to customers around the world. Our innovative developers use modern technology to develop unique, efficient and economical customized seawater reverse osmosis units. Our engineers tailor seawater reverse osmosis systems for you.

➣Is there a solar seawater reverse osmosis system?

Solar reverse osmosis systems are very beneficial because they can reduce operating costs and help protect the environment. Solar desalination is mainly achieved through direct or indirect means. Solar distiller is a well-known device that uses direct solar energy to convert seawater into finished water.

Solar seawater reverse osmosis units are characterized by indirect use of solar energy to desalinate seawater. Solar collectors, photovoltaic power generation, and batteries are used to absorb solar energy, convert heat energy into electricity, and store energy, respectively. Our solar seawater reverse osmosis systems offer a variety of flow rates for a variety of applications such as homes, emergency response, hotels, car washes, etc.

➣Can seawater reverse osmosis systems desalinate salt water?

There are reverse osmosis systems specifically designed for brackish water desalination. The pressure pumps in a brackish water RO system are not as complex as those in a seawater RO unit. In addition, the TDS (total dissolved solids) level of a brackish water RO system ranges from 1,000ppm to 15,000ppm. For better results and maximum resource utilization, it is recommended that you use a saltwater system to desalinate brackish water and a dedicated seawater RO unit to desalinate seawater.

➣Where can I buy a seawater RO system?

Buy all the water treatment equipment you need at FupengWater and enjoy excellent pre-sales and after-sales service, quality products and great discounts. We are a one-stop water treatment system supplier with customers in more than 100 countries.

To ensure quality, we produce most of our components in-house and only work with reputable and well-known manufacturers. FupengWater is ISO 9001:2015 certified and all seawater RO systems are repeatedly tested.

We can provide quotes if needed, and our engineers also provide technical support to guide customers in making the right choice.

The nanofiltration systems are skid-mounted nanofiltration units. They are also ideal for residential applications due to their mobility, ease of installation, and cost-effectiveness. We produce a wide range of standard versions and also offer custom solutions.

➣ How do nanofiltration systems differ from ultrafiltration systems?

Ultrafiltration, nanofiltration, and reverse osmosis systems are the main membrane-based water treatment processes. However, there are fundamental differences between them, making them suitable for different water treatment applications. Ultrafiltration is primarily used to remove viruses, bacteria, and other protozoa, while nanofiltration systems are used to remove organic matter, viruses, and divalent ions. The easiest way to differentiate between nanofiltration and ultrafiltration systems is by the membrane pore size. The filter pore size in an ultrafiltration system is approximately 0.01 microns, while the pore size of a nanofiltration filter is approximately 0.001 microns.

➣ What is the ideal operating pressure for a nanofiltration system?

Nanofiltration water treatment is driven by pressure. High pressure is required to force the influent water through the nanofiltration membrane for filtration. The amount of pressure required depends on the influent volume. Therefore, the transmembrane pressure of different nanofiltration units ranges from 50psi to 225psi (3.5 to 16 bar). A key advantage of nanofiltration systems compared to reverse osmosis systems is that they operate optimally at low pressures. This allows them to reduce power consumption and thus be more cost-effective.

➣Are nanofiltration systems suitable for domestic use?

The main advantage of nanofiltration systems is their excellent multivalent ion removal rate (90-98%). Therefore, they are an ideal solution for domestic water softening. By removing magnesium and calcium ions from raw water, nanofiltration systems can save household detergents and early replacement of appliances such as kettles. For domestic water treatment, FupengWater has a range of conventional small-scale nanofiltration systems.

➣Do you offer industrial nanofiltration systems?

At FupengWater, you have unlimited access to advanced industrial water treatment solutions including nanofiltration equipment. Our industrial nanofiltration equipment is designed for continuous filtration of large volumes of industrial water.

For medium and large industrial applications, our nanofiltration systems offer membranes of different capacities (190,000 to 800,000 GPD). The membrane diameter is typically 8 inches and the maximum operating pressure is 300psi.

Currently, our nanofiltration systems serve various industries such as dye separation, industrial wastewater treatment, and ultrapure water production. For more information, please contact us.

➣What is the energy consumption of nanofiltration systems?

The latest breakthroughs in nanofiltration systems provide stakeholders with a water treatment solution with lower energy consumption. Compared with other water treatment processes (especially reverse osmosis), nanofiltration technology can produce high-purity product water with lower power consumption (about 30%).

In fact, the energy consumption of a typical nanofiltration system ranges from 0.3 cubic meter kWh to 1 cubic meter kWh. However, due to different choices of power supply voltage and frequency, power consumption in different regions is expected to vary greatly. In addition, the flow rate and amount of water treated per day will also have a fundamental impact on the daily electricity cost.

➣What are the payment terms for nanofiltration systems?

We don’t want to lose potential customers due to disagreements on payment terms or payment structure. To this end, FupengWater has developed a number of flexible payment terms to facilitate the customer’s shopping experience.

FupengWater large-scale nanofiltration systems require 50% advance payment, 30% after remote equipment inspection, and full payment before the system is shipped. Traditional small-scale nanofiltration systems require full payment before shipment.

FupengWater welcomes any constructive suggestions on payment terms or payment structure. If you have any questions, please contact our customer service team by emailing info@FupengWater.com.

➣ Do you ship nanofiltration systems abroad?

Shipping delicate and large equipment can be very troublesome. As a caring partner, FupengWater will deliver your order directly to your door, saving you the trouble of customs clearance and finding a reliable courier.

No matter where you are, FupengWater can deliver your nanofiltration system to you safely and quickly. At present, our products have covered more than 100 countries/regions around the world, covering all continents. In addition, we are constantly expanding our delivery routes to expand our service coverage.

➣Can I customize my nanofiltration system?

By incorporating 3D computer modeling technology into the production process, our engineers are able to manufacture NF systems in almost any form. FupengWater continues to turn users' dreams into reality by providing quality customized systems. To help our engineers customize your order, you need to provide the following information:Our engineers will provide the perfect customized nanofiltration solution for your project, which is trustworthy. For further consultation, please contact

our engineers.

Expected impurity rejection rate, flow rate and system capacity.

Power frequency and voltage specifications in your country.

Your feed water composition and expected drinking water quality.

➣Is the nanofiltration system protected by warranty?

It is fair and reasonable for an important system like the nanofiltration system to be protected by a reliable warranty policy. When purchasing nanofiltration equipment from FupengWater, you can enjoy a warranty period of at least 12 months. Under our warranty policy, users have the right to complain about the quality of the equipment and request repair of defective parts.

For your damaged system to be eligible for warranty repair, the nature of the failure must be technical, not human. Failures caused by improper human operation are not covered by the warranty.

➣Do you help install the nanofiltration system?

We provide different forms of installation services depending on the severity of the need and geographical restrictions. First, FupengWater manufactures turnkey NF systems, which are delivered in a fully assembled form. Such systems, as well as small systems, do not require technical installation services. With reference to our detailed installation manual, you will find that the installation process is very simple and time-saving.

For traditional large-scale NF systems that require on-site installation, we will send an experienced and professional team to install them. The installation service fee will be negotiated in advance to allow you to make adequate planning.

In addition, we also provide free virtual installation assistance. We provide multiple video tutorials that detail the installation process of the NF system, and our engineers can also provide on-site installation guidance via video calls.

➣Can nanofiltration systems treat seawater?

In seawater treatment, nanofiltration is mainly used in the pretreatment stage to remove divalent ions that cause equipment scaling. Nanofiltration systems alone cannot fully desalinate seawater because their desalination rate is between 30% and 50%.

However, nanofiltration technology can produce high-quality pure water in combination with other seawater desalination processes. For example, NF-RO desalination can reduce the TDS level of seawater from over 35,000ppm to 500ppm or less. In this hybrid system, nanofiltration technology can remove 90-99% of divalent ions, while reverse osmosis technology can remove up to 99.7% of dissolved solids in seawater.

➣Can nanofiltration systems recycle feed water?

Unlike ultrafiltration systems, nanofiltration and reverse osmosis systems typically recycle different proportions of feed water. For example, experiments testing the water recovery rate (WRR) of nanofiltration systems under optimal conditions (15bar pressure and 554L/h flow rate) showed a maximum WRR of 75%.

This further enhances the reputation of nanofiltration systems as a cost-effective water treatment solution. However, the water recovery rate of nanofiltration systems can vary greatly depending on the pressure and the degree of nanofiltration membrane fouling.

➣What are the disadvantages of using nanofiltration systems?

The advantages of nanofiltration systems are obvious and far outweigh their limitations. The biggest criticism of nanofiltration systems has long been their low salt retention and inability to adequately remove monovalent ions. Below we will explore some of the other limitations of nanofiltration systems.

➣Do you produce spare parts for nanofiltration systems?

By choosing FupengWater as your preferred purchasing partner for nanofiltration systems and related products, you will receive unlimited customized repair parts. In addition to system quality assurance, we also guarantee 100% compatibility.

Production is mainly completed in-house, which helps us maintain high quality standards. Spare parts available for NF systems include: NF membranes, membrane housings, flow meters, interconnects, etc.

➣What is the expected life of a nanofiltration system?

When investing in a water treatment system, most users first consider the service life of the system. Fortunately, nanofiltration systems are very durable, with service lives ranging from 15 years to about 20 years. Nanofiltration membrane elements are also equally durable, with a service life of more than three years, depending on the quality of pretreatment and anti-fouling measures.

From an investment perspective, nanofiltration systems are almost perfect choices with low maintenance costs. Therefore, users can ensure a quick and sufficient return on investment.

The energy consumption rate of nanofiltration systems is 3 – 1 kWh/m³, which consumes more electricity than ultrafiltration systems.

When treating highly contaminated feed water, spiral wound NF membranes require pretreatment.

Compared to RO membranes, NF membranes are relatively expensive.

FupengWater nanofiltration systems are made of durable materials and can serve you for a long time. We guarantee to provide you with the best water treatment process. With our nanofiltration systems, you can expect satisfactory treated water. We are a trusted manufacturer of nanofiltration systems.

We have extensive experience in manufacturing large and easy-to-operate nanofiltration systems and other related equipment. As an experienced manufacturer and supplier, we are able to provide you with the required nanofiltration system according to your application requirements.

As your partner, it is our responsibility to provide you with the only high-quality and easy-to-operate nanofiltration system. These nanofiltration systems can remove organic molecules and even viruses and bacteria from water. It can also remove various salts. Its specifications can be customized according to your specific application needs.

These nanofiltration systems are usually used to soften hard water. FupengWater consists of professional staff and manufacturers to ensure that the nanofiltration system can play its precise function in any application. We have high-tech equipment to perfectly customize your exclusive nanofiltration system.

You can have your desired nanofiltration system at an affordable price. FupengWater also ensures short delivery time and safe packaging of the nanofiltration system. We will assist you all the way until you receive the purchased nanofiltration system. We have a professional team and have completed the order processing.

FupengWater is your trusted manufacturer and partner, and we will never let you down. We are committed to satisfying you with the quality and operation of the nanofiltration system we launch. It will undoubtedly make your water treatment work easier. Our sales team is ready to serve you and is always ready to answer your inquiries.