Industrial reverse osmosis systems can remove up to 99.9% of salt and contaminants from various impure water sources (such as municipal water, salt water and surface water). The system can block bacteria, particles, sugars

Industrial reverse osmosis systems can remove up to 99.9% of salt and contaminants from various impure water sources (such as municipal water, salt water and surface water). The system can block bacteria, particles, sugars, proteins, dyes, and impurities with a molecular weight of more than 150-250 Daltons.

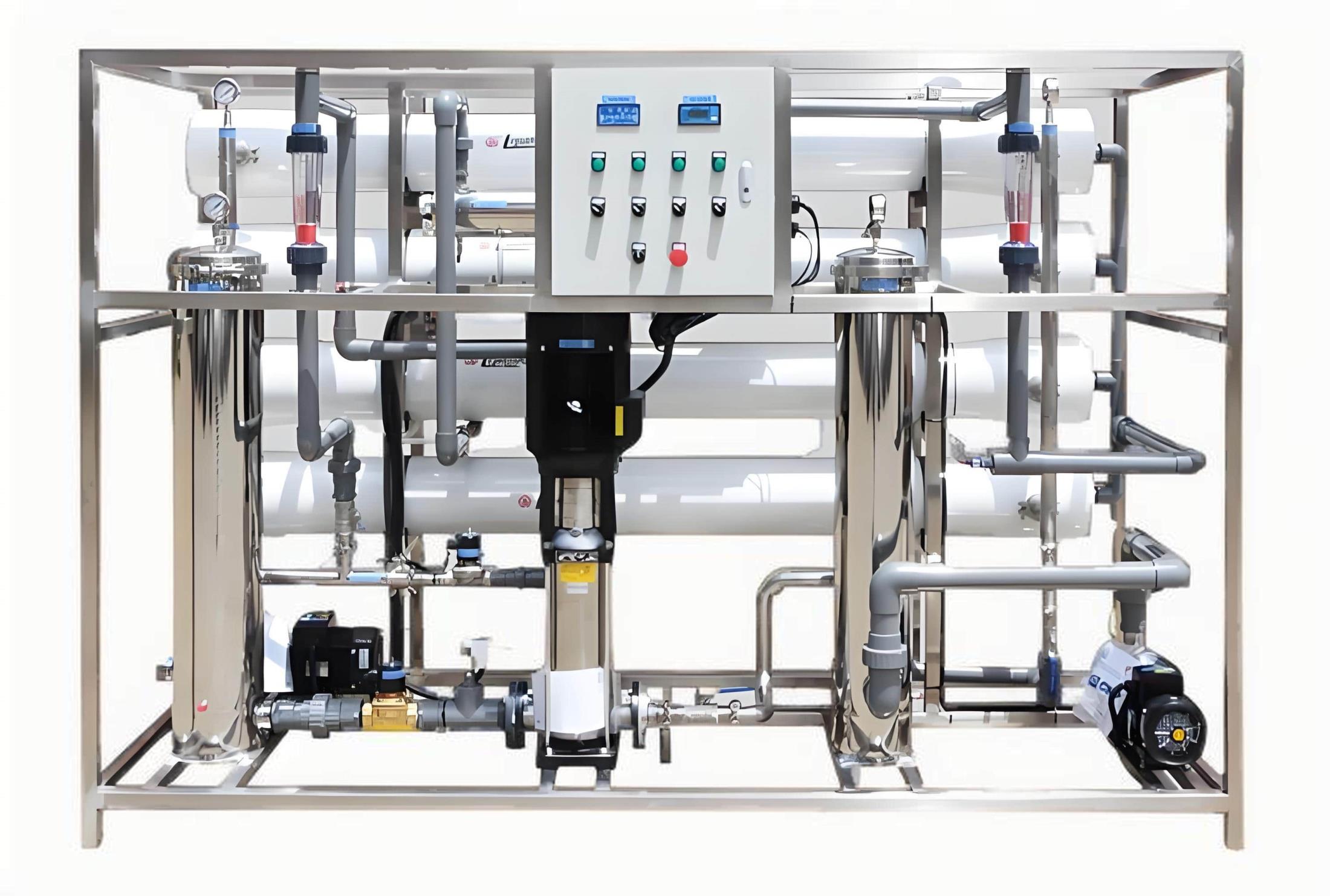

FupengWater offers a variety of prefabricated and customized industrial reverse osmosis systems with a processing capacity ranging from 28,000 gallons per day to 1,000,000 gallons per day. These energy-efficient industrial reverse osmosis units can meet the needs and applications of various industrial water treatments and produce high-quality water at an affordable cost.

Our industrial reverse osmosis systems are designed to produce high-quality water in the most demanding continuous operation and corrosive environments. These reverse osmosis units are first-class systems dedicated to providing the most advanced solutions in the water treatment industry. They also have optional functions, control features and additional devices to facilitate users to customize the reverse osmosis equipment. Whatever your water treatment application needs, our industrial reverse osmosis systems are ideal.

Equipment for tap water, brackish water and seawater, equipped with media filters and chemical dosing systems (including pre-chlorination, antiscalant addition, dechlorination, post-chlorination and post-pH adjustment). The equipment is mainly customized according to customer needs and different water treatment applications. Our equipment uses advanced energy-saving membranes and is recognized as one of the most efficient industrial reverse osmosis systems on the market.

When designing industrial reverse osmosis systems, factors such as rugged construction, user-friendly design, environmentally friendly materials and long-term reliability are fully considered.

We provide fully containerized/mobile reverse osmosis water treatment systems, which are assembled in containers that meet ISO standards. Each container is customized according to specific water treatment applications and has the characteristics of easy installation and operation, high efficiency, small footprint, energy saving and environmental protection.

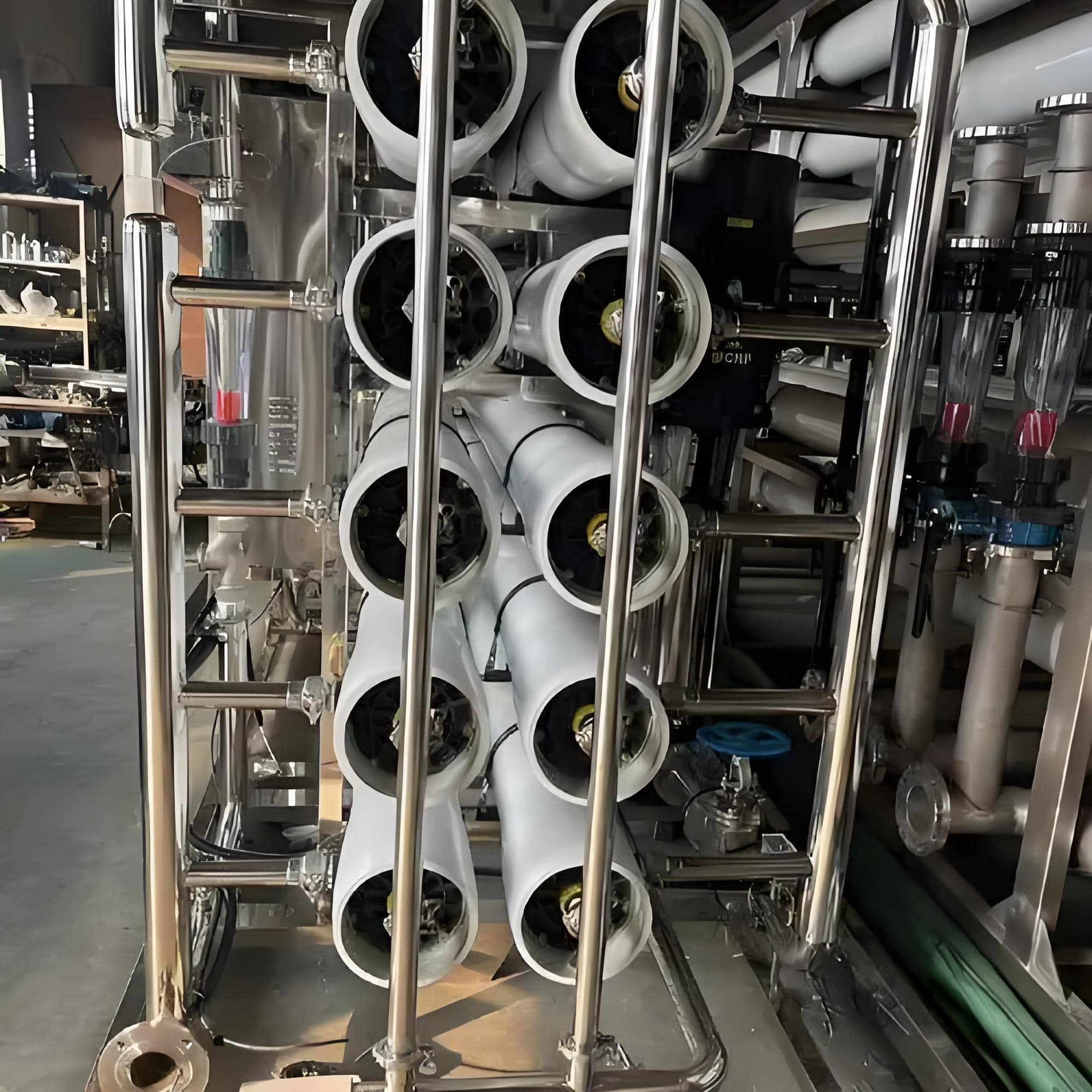

Industrial reverse osmosis equipment includes multi-media pre-filters, water softeners or antiscalant dosing systems, dechlorination dosing systems, reverse osmosis devices with semi-permeable membranes, and ultraviolet disinfection devices or post-chlorination equipment as post-treatment. These RO units use reverse osmosis technology to first send the incoming water to a multimedia pre-filter to remove particles larger than 10 microns. Next, antiscalants are injected into the water to control hardness fouling that can damage the RO unit membrane. These pre-treatment solutions can remove hardness, chlorine, odor, color, iron and sulfur. The water then enters the RO unit, where a high-pressure pump applies extremely high pressure to the highly concentrated solution to separate out the remaining salts, minerals and impurities that the pre-filter failed to capture. Fresh drinking water flows out of the low-pressure end of the membrane, while salts, minerals and other impurities are discharged from the drain at the other end. Finally, the water passes through a UV sterilizer (or post-chlorination) to kill any remaining bacteria and microorganisms in the water.

Industrial RO systems are cost-effective and use the latest RO technology to remove dissolved salts, particles, organic matter, minerals, tannins, solids and other impurities from the water. Industrial RO system manufacturers use RO membranes as the core separation technology to block these impurities. FupengWater uses products from many of the world's leading membrane manufacturers.

As part of our industrial line, RO units have capacities ranging from 29,000 to 185,000 gallons per day with feed water total dissolved solids (TDS) concentrations ranging from 900 to 5,000 ppm. These RO units come standard with pre- and post-treatment components. In addition, we offer customization options such as higher feed water TDS, lower water temperatures, future expandability, variable pressure designs with VFDs, BMS system outputs, data logging, and remote monitoring.

To select the right RO model, please provide the following information:

Flow rate: GPD (gallons per day), m³/day, etc.

Feed water TDS and water analysis: This information is critical to prevent membrane fouling and help us select the right pre-treatment.

Iron and manganese: Iron and manganese must be removed from the water before it enters the RO unit.

TSS: Must be removed before entering the industrial RO system.

Feed water SDI: Must be less than 3.

Grease: Water should not contain grease.

Chlorine: Must be removed.

Available voltage, phase and frequency: Such as 208, 220, 460, 380, 415V.

Projected area size for installation of industrial RO system.

Maximum inlet water temperature: 42°C.

Upgrade of equipment with TDS exceeding 5,000 ppm.

Hydrogen Sulfide (H₂S): Must be removed.

Maximum silica tolerance: 60 ppm @ 60% recovery.

Feed water TDS: 0 - 1,000, 3,000, 5,000 ppm.

Operating pressure: 150 to 250 psi.

pH tolerance: 3 - 11.

Maximum iron content: 0.05 ppm.

Inlet pressure: 20 to 80 psi.

Hardness above 1 GPG: Antiscalant needs to be added.

Turbidity: Must be removed.

Operate at higher TDS by reducing recovery.

Standard Features:

Programmable time delays and set points

Motor starter

Stainless steel multistage pump with TEFC motor

FRP membrane housing

5 micron element pre-filter

460V/3Ph/60Hz power supply

Microprocessor based control panel

NEMA 12 enclosure

Low pressure switch

High pressure switch

Fill pressure gauge

Permeate conductivity monitor

Permeate and concentrate flow meters

Powder coated carbon steel frame

8 inch TFC spiral wound membrane

Hourly automatic flushing

Available Options:

Feed/Permeate Blending

UV Sterilization System

Water Softener

Feed or Product pH Monitor with Sensor

Feed ORP Monitor with Sensor

Chemical Dosing System

Media Pre-Filtration System

Post-Deionization Polisher

Skid Mount with Pre- or Post-Treatment

Remote Monitoring

Feedwater Conductivity Monitor

Membrane Cleaning Skid

220V or 380 - 415V/3 Phase/50Hz

Product Tank Level Controller Switch

Industrial RO units feature rugged components, 8-inch TFC spiral wound membranes, advanced control panels, industrial water pumps, and corrosion-resistant components. Industrial RO water filtration systems are ideal for the following applications:

EDI pretreatment

Rinse water

Pharmaceuticals

Boiler feed water

Laboratory water purification systems

Chemical mixing

Cooling towers

Ion exchange pretreatment

Stormwater treatment

Well water treatment

Food and beverage

Ice making

Refinery water treatment

Nitrate removal from water

Electronics/metal finishing

Mining

Beverage production and bottled water

Spot-free product rinse

Copyright 2025 All Right Reserved. Hebei Fupeng Environmental Protection Technology Group Co., LTD