A conveyor belt is the carrying medium of a belt conveyor system (often shortened to a belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums)

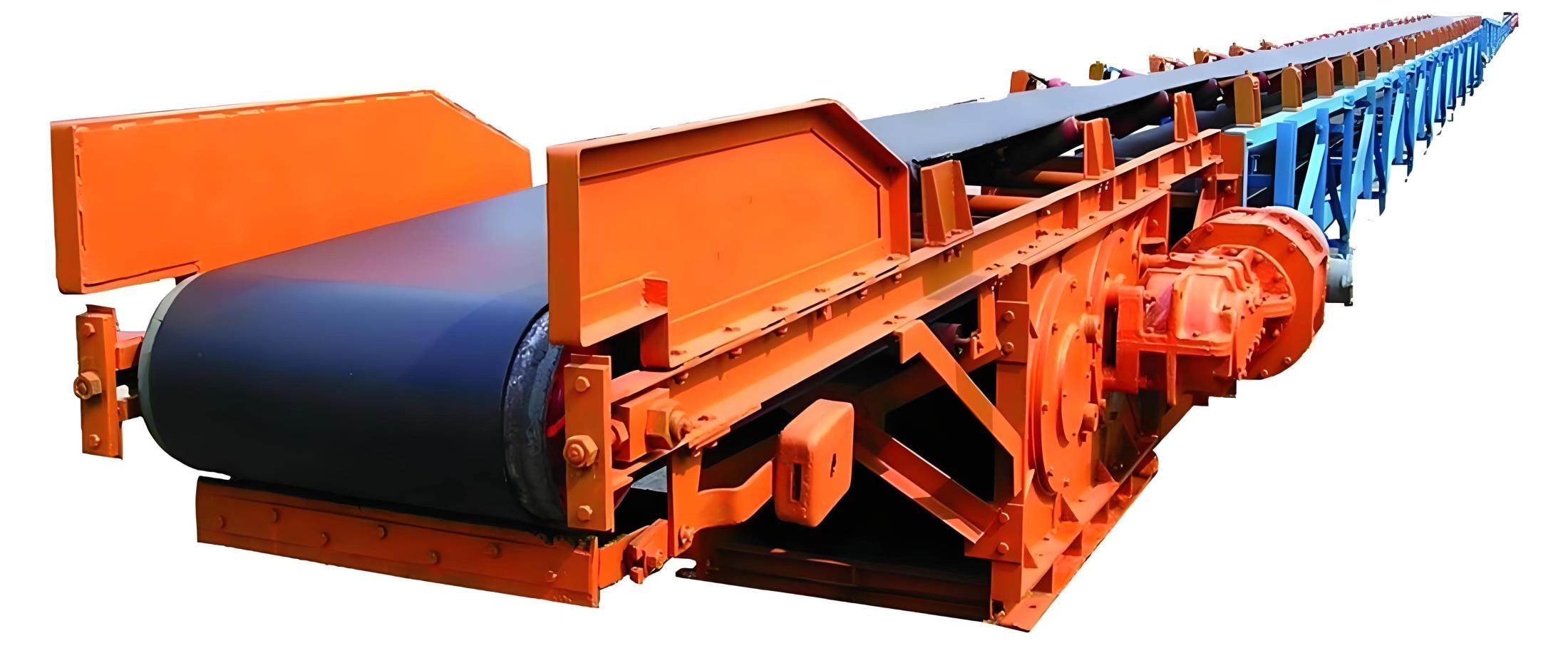

PDJ belt conveyor is suitable for chemical, metallurgical, coal mining, hydropower, building materials and other departments. It can transport various bulk materials such as blocks and granules. Therefore, it is often matched with screens or dewatering machines in urban sewage to transport screen residue or dewatered sludge.

The equipment adopts a continuous trough belt type. The material falls onto the conveyor belt from the grille or the dehydrator discharge port. Driven by the electric roller, the material moves from one end to the other, and the end is connected to the garbage bin for further processing.

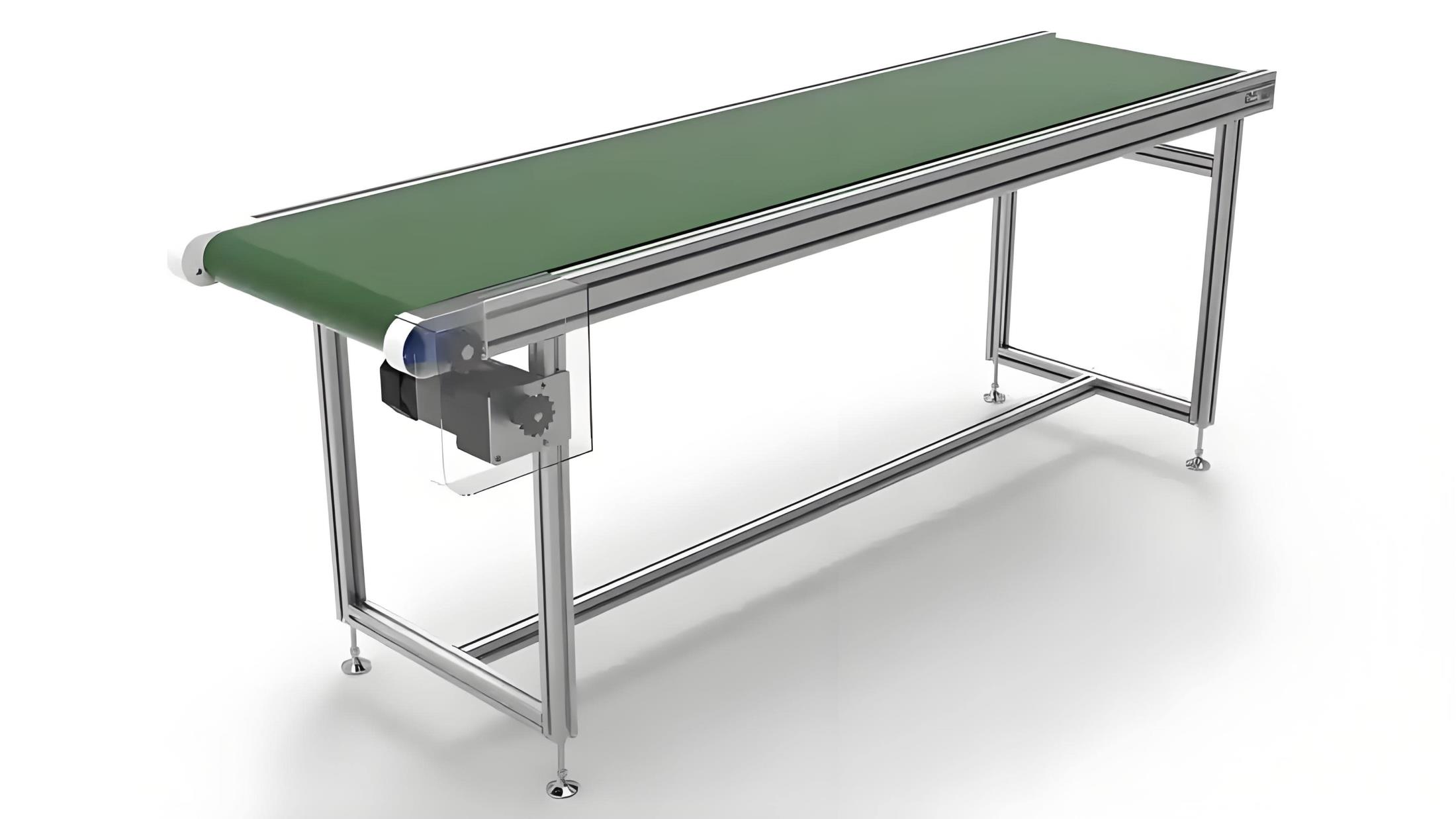

Belt conveyors are widely used in metallurgy, coal, transportation, hydropower, chemical industry, environmental protection and other industries to transport loose materials or finished goods. According to the requirements of the conveying process, they can be transported by a single unit, or they can be combined with other conveying equipment to form a horizontal or inclined conveying system. In addition to pure material transportation, they can also be coordinated with the requirements of the process in the production process of various industrial enterprises to form a rhythmic flow operation transportation line.

1. High conveying efficiency, improve production efficiency.

2. Strong adaptability, belt conveyor is suitable for conveying various materials.

3. High flexibility, different lengths and angles can be set according to different situations.

4. Low maintenance cost.

5. Environmental protection and energy saving.

On the floor.

Common carbon steel materials for racks

Commonly used 220V and 380V, can be customized as needed.

The belt conveyor is mainly composed of two end rollers and a closed conveyor belt tightly sleeved thereon. The roller that drives the conveyor belt to rotate is called an electric roller (drive roller); the other roller that only changes the direction of movement of the conveyor belt is called a redirecting roller. The drive roller is driven by an electric motor through a reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase traction and facilitate dragging. The material is fed from the feeding end and falls on the rotating conveyor belt, and the conveyor bag is unloaded at the discharge end by the friction of the conveyor belt.

The belt conveyor is mainly composed of a frame, conveyor belt, rollers, drums, tensioning devices, transmission devices, etc. It can be transported horizontally or upwards, with a maximum conveying angle of about 30°.

Copyright 2025 All Right Reserved. Hebei Fupeng Environmental Protection Technology Group Co., LTD