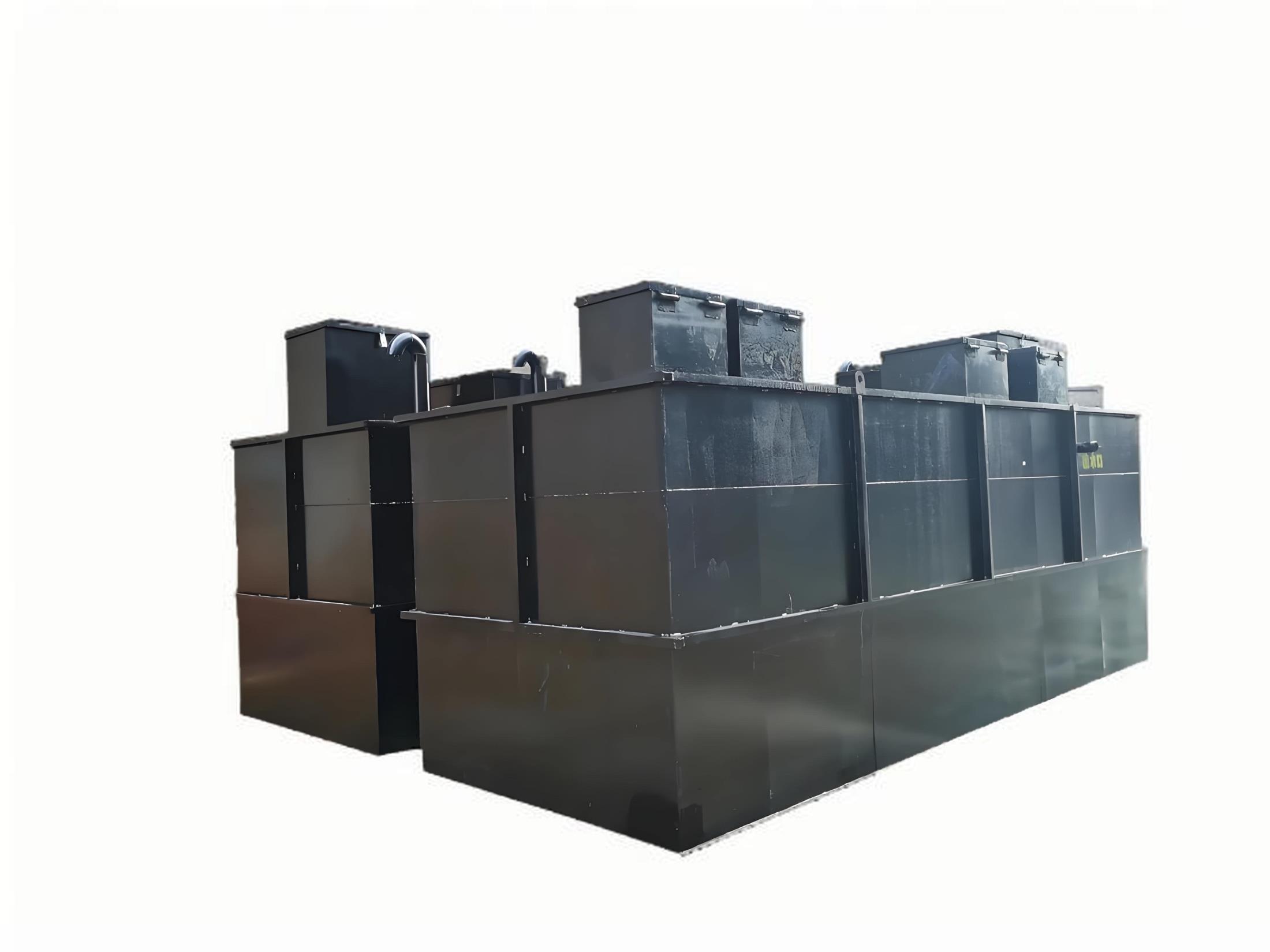

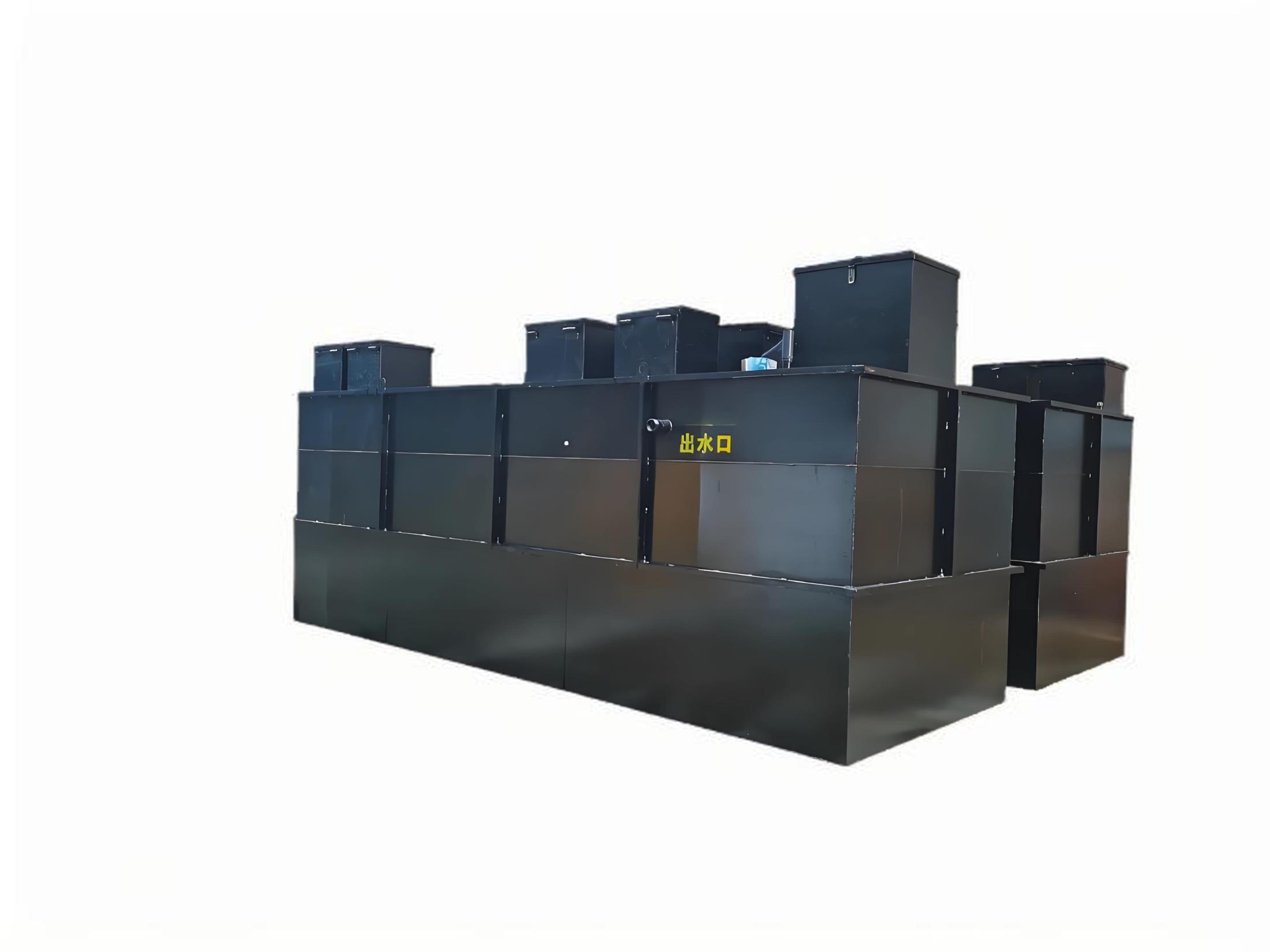

Our company produces WSZ underground domestic sewage treatment equipment in two major series: carbon steel anti-corrosion series and fiberglass reinforced plastic (FRP) series.

Our company produces WSZ underground domestic sewage treatment equipment in two major series: carbon steel anti-corrosion series and fiberglass reinforced plastic (FRP) series. The equipment adopts the world's advanced biological treatment process, integrating the removal of BOD5, COD, and NH3-N into one system, making it the most efficient sewage treatment equipment currently available.

It is widely used for the treatment of domestic sewage in luxury hotels, villa communities, and residential communities, replacing the chemical tanks with low removal rates that cannot meet the national comprehensive discharge standards after treatment. Field applications have shown that the underground sewage treatment equipment is a highly effective and easy-to-manage device for sewage disposal.

The characteristics of integrated sewage treatment equipment are biological treatment method, by adding anaerobic, anoxic and aerobic microorganisms to the equipment to contact with sewage, providing convenient conditions for microbial growth through automatic procedures, so that microorganisms can split and reproduce, thus achieving the effect of purifying water quality, and the removal rate of pollutants reaches more than 90%. Widely used in business, residential and rural sewage treatment. Common equipment capacity is 1-50 tons/hour.

1, less land, less impact on the surrounding environment.

2, set to remove BOD5, COD, NH3-N in one.

3. High pollutant removal efficiency.

4, simple operation management, low operating costs.

Above-ground type, buried type.

carbon steel anti-corrosion type and glass fiber reinforced plastic type

Commonly used 220V and 380V, can be customized as needed.

Sewage is lifted into the equipment through a sewage pump. The equipment is equipped with an electronic control system, an aeration fan, a reflux pump, a sedimentation device, and a disinfection device. By adding active microorganisms and carrier fillers into the equipment, anaerobic, anoxic, and aerobic microbial flora are cultivated through the different oxygen contents in different links. The pollutants in the sewage are reduced through the reproduction and metabolism of microorganisms. The pollutant removal rate can reach more than 95%.

1. Regulating tank: It receives sewage and regulates water quality and quantity. A sewage lifting pump and a liquid level control system are installed in the tank.

2. Anaerobic, anoxic and aerobic areas: They are distinguished according to the different oxygen content of sewage in the area. The oxygen content of the anaerobic tank is less than 0.2mg/L, the oxygen content of the anoxic tank is less than 0.5mg/L, and the oxygen content of the aerobic tank is ≥2.0mg/L. Microbial carrier fillers and reflux pumps are installed in the tank, and aeration fans are equipped in the aerobic tank.

3. Sedimentation tank: The effluent of the aerobic tank is separated from the mud and water by gravity sedimentation, and the precipitated sludge is disposed of, and the supernatant enters the disinfection tank. Settlements are set in the tank. Inclined tube fillers or central tubes are set.

4. Clear water tank: After disinfection by adding disinfectants, the water meets the discharge standards. Equipped with disinfection dosing devices.

1. The equipment foundation pit needs to be flat, and a concrete foundation with a thickness of 300mm needs to be set at the bottom.

2. After the underground integrated equipment is in place, the equipment needs to be filled with water to prevent water from entering the foundation pit during the rainy season, causing the equipment to float or dislocate.

3. After the equipment inlet and outlet pipes are connected, water testing is carried out. Only after confirming that the installation is correct can backfilling be carried out. Pipeline protection measures need to be taken during backfilling to prevent the backfill soil from damaging the pipeline.

4. After backfilling, the equipment manhole needs to be exposed 150-200mm above the ground.

Copyright 2025 All Right Reserved. Hebei Fupeng Environmental Protection Technology Group Co., LTD