- 2025-07-09

absorb

The water treatment mechanism in the absorption process

Core definitions and mass transfer principles

Absorption refers to the process by which contaminant molecules dissolve through a phase interface and diffuse into the bulk liquid phase, with the following technical characteristics:

Distinction from adsorption:

Parameter Absorption Adsorption

Site of action Overall liquid phase Solid phase surface

Driving force Concentration gradient/Henry's law Van der Waals forces/Chemical bonds

Kinetics Gas-liquid mass transfer controlled Pore diffusion controlled

Water treatment application model

■ Removal of gaseous pollutants

Target substance Adsorbent Reaction equation Removal rate

NH₃ H₂SO₄ solution 2NH₃ + H₂SO₄ → (NH₄)₂SO₄ >99%

H₂S NaOH solution H₂S + 2NaOH → Na₂S + 2H₂O 95-98%

CO₂ MEA solution CO₂ + 2HOCH₂CH₂NH₂ → HOCH₂CH₂NHCOO⁻ + HOCH₂CH₂NH₃⁺ >90%

■ Key engineering parameters

Mass transfer coefficient (Kₗa): 0.005-0.03 s⁻¹ (packed tower conditions)

Henry constant (H): Determines gas-liquid equilibrium (NH₃: 0.76 atm·m³/mol)

Liquid-to-gas ratio (L/G): 1-10 L/m³ (adjusted based on pollutant solubility)

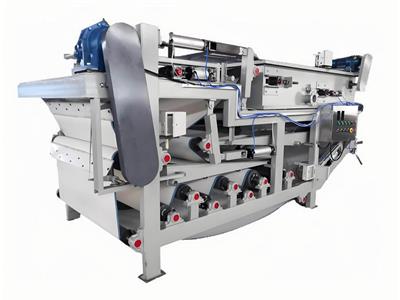

Equipment Design and Operation

Tower type Aplicable scenarios Advantages Limitations

Packed tower Medium-low concentration exhaust gas Pressure drop reduction (ΔP<500 Pa/m) Prone to blockage (SS>50mg/L)

Spray tower Dusty gas Strong anti-blocking capability Low mass transfer efficiency (about 60%)

Bubble column High solubility substances Controllable residence time (10-60s) High energy consumption (>3kW/m³)

Industrial cases

Wastewater treatment plant odor removal system

Absorbent: 5% sodium hypochlorite solution

Design load: H₂S 200ppm → outlet <5ppm

Filler height: ≥3.5m (ensuring contact time >8s)

Flue Gas Desulfurization (WFGD)

Limestone slurry concentration: 15-20%

SO₂ removal efficiency: >98% (pH maintained at 5.2-5.8)

Demister requirements: Liquid carryover <50 mg/Nm³