- 2025-07-09

Acidic Water Causes and Treatment Technologies

Acidic Water Causes and Treatment Technologies

Definition and Formation Mechanism

Acidity Determination: pH < 7.0 (Standard Conditions at 25℃)

Natural Causes:

Atmospheric precipitation: CO₂ + H₂O → H₂CO₃ (carbonic acid, pH≈5.6)

Geological permeation: Flowing through calcium-poor formations (granite areas) results in lack of buffering capacity

Human factors:

Acid mine drainage (AMD): FeS₂ oxidation produces H₂SO₄ (pH can be as low as 2.0)

Industrial acid pickling wastewater

Quantification of corrosion risk

Material type Corrosion rate at pH=5.0 Typical damage manifestation

Copper pipe 0.8mm/year Blue-green stains (copper carbonate hydroxide)

Galvanized steel pipe 1.2mm/year Red rust penetration (lifespan < 3 years)

Stainless steel 304 0.05mm/year Pitting corrosion (worsens when Cl⁻ > 200mg/L)

Neutralization treatment technology

■ Mineral neutralization method

Neutralizing Medium Reaction Equation pH Enhancement Efficiency

Limestone (CaCO₃) CaCO₃ + H₂CO₃ → Ca²⁺ + 2HCO₃⁻ 0.8-1.2 pH increase per g/L medium

Dolomite CaMg(CO₃)₂ + 2H₂CO₃ → Ca²⁺ + Mg²⁺ + 4HCO₃⁻ Slow-release neutralization prevents sudden pH rise

■ Engineering Control Parameters

Contact time: ≥3 minutes (limestone filter bed)

Particle size requirement: 1-3mm (prevents clogging and ensures reaction area)

Alkalinity increment: Target effluent alkalinity ≥50 mg/L (as CaCO₃)

Home protection plan

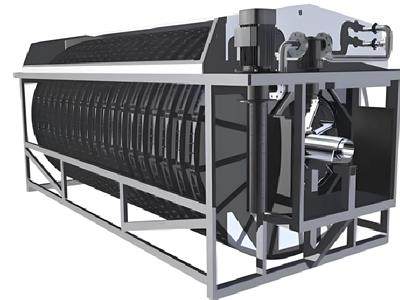

Neutralization filter tank:

Calcium and magnesium mineral filter media layer height ≥ 800mm

Empty bed contact time (EBCT) ≥ 2 minutes

Automated control:

Real-time pH monitoring (accuracy ±0.1) linked with sodium carbonate dosing

Target pH 7.0-8.5 (corrosion and scaling balance point)